Domestic Affiliates

Technology for a better tomorrow

Aluko Co.,ltd

ALUKO has been leading the acceleration and diversification of industry ranging from the development/production of the weight lightened components for automobiles, vessels and rapid electronic railways to those of 650mm mega extruded shape which is the highest in the orient,various electric &electronic/communication components and building materials.

From casting raw materials for aluminum extrusion to processing and assembly of final parts

Industrial materials

Built-in Top-Chassis for LCD TVs

Built-in Edge-bar for LED TVs

Heat-Sink for Electronics

Laptop, External Case for Electronics (Mobile phone, etc.), Front panel

Industrial motor case

Solar collector frame

Spheres for High-speed railway car

Automotive lightweight parts

LNG ship storage tank material

General railing, vehicle fence, road railing

General fence, child fence, bicycle road fence, port security fence

Overpass Exterior, Bridge Exterior, Soundproof Wall, Canopy

Public facilities (bus platform, sculpture, pagora, inspection road, etc.)

Street lights (park lights, image poles, low light, road lights, landscape lighting, etc.)

Smartphone case material sale

Aluminum body frame

Energy storage case

Electric car battery case

Material / Machine

Car / Transportation

Electrical / Electronic

Civil / Construction

Ground Mounted Fixed System

Rooftop Close-type Mounted System

Rooftop Mounted System

BIPV

Building material

Aluminum Sash - DongYang ALU SASH

The aluminum chassis is the number one choice for perfect insulation, fuel savings and perfect tightness of noise and leaks.

Dongyang PRIMO

It's light and strong, it doesn't change color over time and it's economical.

DONGYANG System Window

High quality chassis suitable for luxury home

Dongyang System Windows is a high quality chassis with excellent thermal insulation, convenient features and a sleek design.

'DONGYANG iWALL' is a new concept building exterior wall system utilizing only the advantages of 'ALU SASH' and 'PRIMO SASH'.

It is an eco-friendly curtain wall system that has excellent insulation and airtight performance by applying internal double insulation method to environmentally friendly aluminum.

FA Business

반도체 소자 및 모듈 IC 등을 자동으로 외부의 테스트 장치에 전기적으로 접속하여 테스트하는 장비

정밀도 : 50㎛

핵심기술 : Sorting 기술 (양품, 불량) 가혹조건 Test (-40℃ ~ 125℃)

Final Test와 연계하여 Device 등급별로 분류하는 설비

정밀도 : 50㎛

핵심기술 : Sorting 기술 (양품, 불량) 가혹조건 Test (-20℃ ~ 80℃)

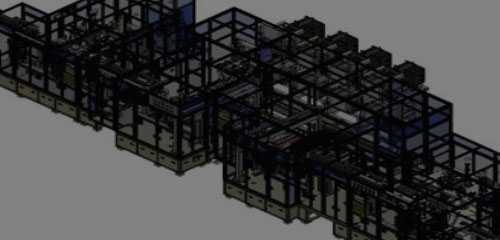

Display Panel 제조를 위한 Photo 공정 중 PI 고점도 코팅액을 도포하는 공정에 Glass를 반송하는 장비

구성 : Entrance CV, Neutral CV, Eximer UV CV, TURN Stage, Exit CV, Fence류

Line 길이 : 44m

Display Panel 제조를 위한 Photo 공정 중 코팅액을 도포하는 공정에 Glass를 반송하는 장비

구성 : Entrance CV, Neutral CV, Eximer UV CV, IR-UV CV, Diverter CV, TURN Stage, Pin Stage, Exit CV, Fence류

Line 길이 : 110m

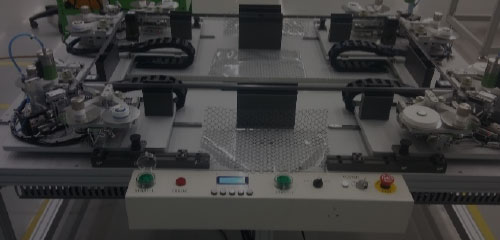

삼성 TV Frame 코너 리터치를 자동으로 작업하는 장비

리터치 : 코너에 잉크로 도포하는 작업

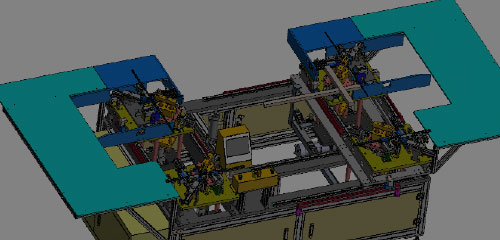

알루미늄 TV Bezel 제품을 90º 벤딩 및 90º 형상을 유지하기 위한 벤딩부 코킹을 실시하는 장비

[ Electrode Line ]

- 전극에 코팅 및 압착을 한 다음 원하는 크기로 절단한 전극을 여러 개 쌓아 양극(+), 음극(-) 극판을 만드는 공정

- 구성 : Coater, Pressing, Slitter, Notching, Stacking

[ Packaging(PKG) Line ]

- 양극(+), 음극(-) 극판이 만들어진 Cell에 Tap을 용접한 다음 AL Pouch로 외장을 만들어 전해액을 주입하여 완성품을 만드는 공정

- 구성 : Tap Welding, Cell Assy, EL Filling, Wetting, V-Sealing

[ Degass ]

- 충/방전 공정을 거치는 동안 전지내에 축척된 가스를 상온에서 배출시키는 공정

- 구성 : Degassing, Folding, Press, Test

Leading the material of housing culture.

Hyundai Aluminum

Since 1978, Hyundai Aluminium Co has been manufacturing Curtain Wall which will magnificently decorate the exterior of building and Al-Form which will raise construction efficiency to the utmost extent.

Hyundai Aluminium Co is equipped with One-Stop-System covering design, fabricating, assembling, construction to meet the demand of customers and highly qualified technicians/engineers.

Hyundai Aluminium Co has constantly accumulated experience and technology from numerous 10 million dollar projects in and outside the country.

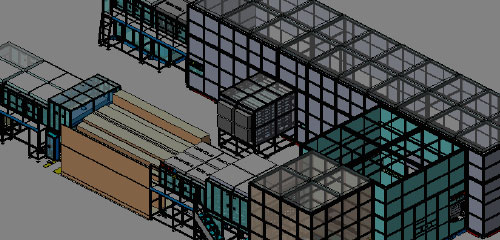

Aluminum Curtain Wall

From production of curtain wall bars to flawless design and construction

Curtain Wall is a 'wall' under the Building Standard Law, specifically a non-load-bearing external wall which is weatherproof/soundproof/adiabatic and a modern architecture using glass, etc to cover internal structure.

Along with the excellent function as a external material,Curtain Wall is usually attached to skyscrapers.

Curtain Wall requires intensity/durability of the extruded materials to connect/support glass or external wall.

Hyundai Aluminium Co manufactures the well-equipped Curtain Wall with all aspects above, and can provide various products fit for the construction.

AL-Form System

The AL-FORM System shortens the construction period and reduces the cost by simple construction.

AL-FORM was first introduced on site in 1997 in Korea. We will try to break free from the simple material input-oriented formwork market that Euroform has been mainstream.

AL-FORM has played a leading role in the development of the formwork market with a total service that goes one step further from building drawing review to site confirmation. In addition, we are constructing 70,000 households annually as a result of our excellence, and we expect continuous increase in quantity.

Hyundai Aluminum will play an important role in carrying out formwork on site more conveniently and quickly by expanding the AL-FORM area to residential complexes, office buildings, and other structures.

Metal surface treatment specialized company

KPTU

Surface coating is a clean, pollution-free environment-friendly process that uses electricity to improve wear resistance, corrosion resistance, high temperature strength, fatigue resistance, and corrosion resistance. Surface coating is a key area of the manufacturing basic industrial process that can enhance mechanical, physical and chemical properties.

We are developing and operating non-extruded and high-tech parts in order to create high added value from the existing sales of aluminum extrusion molds.

Specialized in aluminum alloy billet casting

Alutec

Starting with our first business in 1995, we have been manufacturing high quality aluminum alloy billets that customers want from small diameter to large diameter based on more than 10 years of experience and technical accumulation.

In addition, as the price of primary aluminum ingot increases due to the increase of raw material price, all employees are doing their best to develop technology to reduce the processing loss as much as possible.

Main business area

Main product

Technology for a better tomorrow

Alu Materials Co.,ltd

Alu Materials has been leading the acceleration and diversification of industry ranging from the development/production of the weight lightened components for automobiles, vessels and rapid electronic railways to those of 650mm mega extruded shape which is the highest in the orient,various electric &electronic/communication components and building materials.